Due to the increasing disease pressure from viruses and fungi in greenhouse farming, thorough and intensive cleaning during crop rotation is becoming increasingly important. To gain a better understanding of material selection and application, we examined how different material options respond to the increasingly intensive use of various cleaning and disinfecting agents, such as in fogging, deck cleaning, gutter cleaning and co-dripping of substances.

The results provide valuable insights into the suitability of the materials, in combination with different chemicals and support optimizing their selection and application.

Traditional coatings, such as polyester and polyurethane, which have been used in Cultivation gutters for many years, are more susceptible to penetration than fully sealed layers, such as a PVC laminate or a polypropylene layer of Second Skin, because of their semi-open structure and solid particles.The porous structure of the coatings allows the agents to penetrate the protective zinc layer or the steel layer. It can also react with the coating itself if it is left in for long periods of time. This increases the risk of damage, for example, if the application time is too long or if too high concentrations are used. The risk increases further if insufficient post-coating rinsing is done. Fully sealed coatings such as PVC or Second Skin offer a more robust and durable alternative for systems with high cleaning and hygiene requirements.

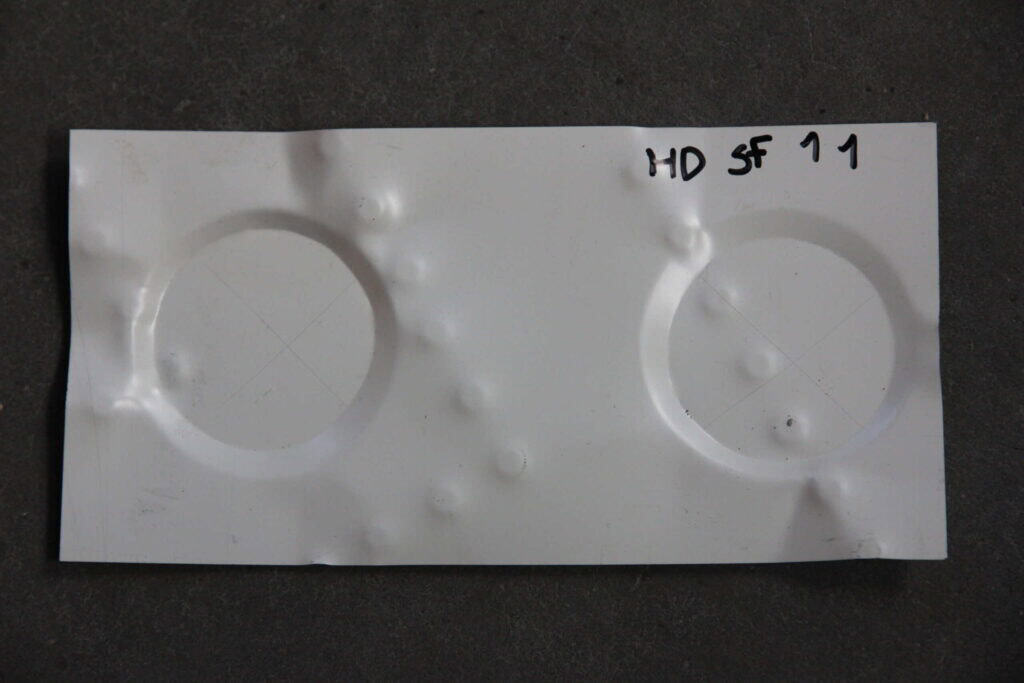

Samples of the different material options were exposed to various cleaning and disinfecting agents. The tests were conducted under realistic conditions, with the samples deliberately deformed and scratched.

During the study, the concentration of the agents was varied: both the supplier’s recommended concentration and an increased concentration (2.5x) were tested. In addition, the application time was also varied: the recommended time (20 minutes), twice the recommended time (40 minutes) and complete evaporation of the agent. The latter simulates the situation where the agent is not rinsed with water.

Each test consisted of a minimum of 5 exposure cycles, during which microscopic observations were made to determine whether blistering, discoloration, (partial) loosening of the coating, or other forms of degradation occurred.

The results of the study clearly show that the different materials react differently to the tested cleaning agents.

Especially in the case of porous coatings, such as polyester and polyurethane, a long soaking time without rinsing leads to an increased risk of damage.

Scratched and deformed surfaces were the first to show signs of deterioration. In contrast, PVC-laminated steel and Second Skin were found to be almost completely resistant to all agents tested.

Agents that are not post-rinsed continue to act permanently. This can cause blistering and (partial) loosening of the coating, especially under the substrate mat.

In addition, it is advised to avoid certain agents. The table below lists the agents tested by Metazet and their active stoffen.

Fill out the form for more information